Starting Out in Data Science

At Abbott, I had the opportunity to explore data generated by the assembly lines and implement a machine learning model to classify chip protrusion. Despite using only 3 of the 4 images used by the off-the-shelf software (and at one-tenth the resolution) my model achieved higher accuracy. During development, I also identified missing data points needed to properly evaluate and compare solutions.

After demonstrating the potential of ML to the team, I was tasked with building a second model to extract multiple features from assembly line images and link them to R&D data. This model was successfully deployed in production via a Docker container. Later, I developed a third model to estimate the location of a chemical pouch, which remained undeployed due to COVID-19 lockdowns.

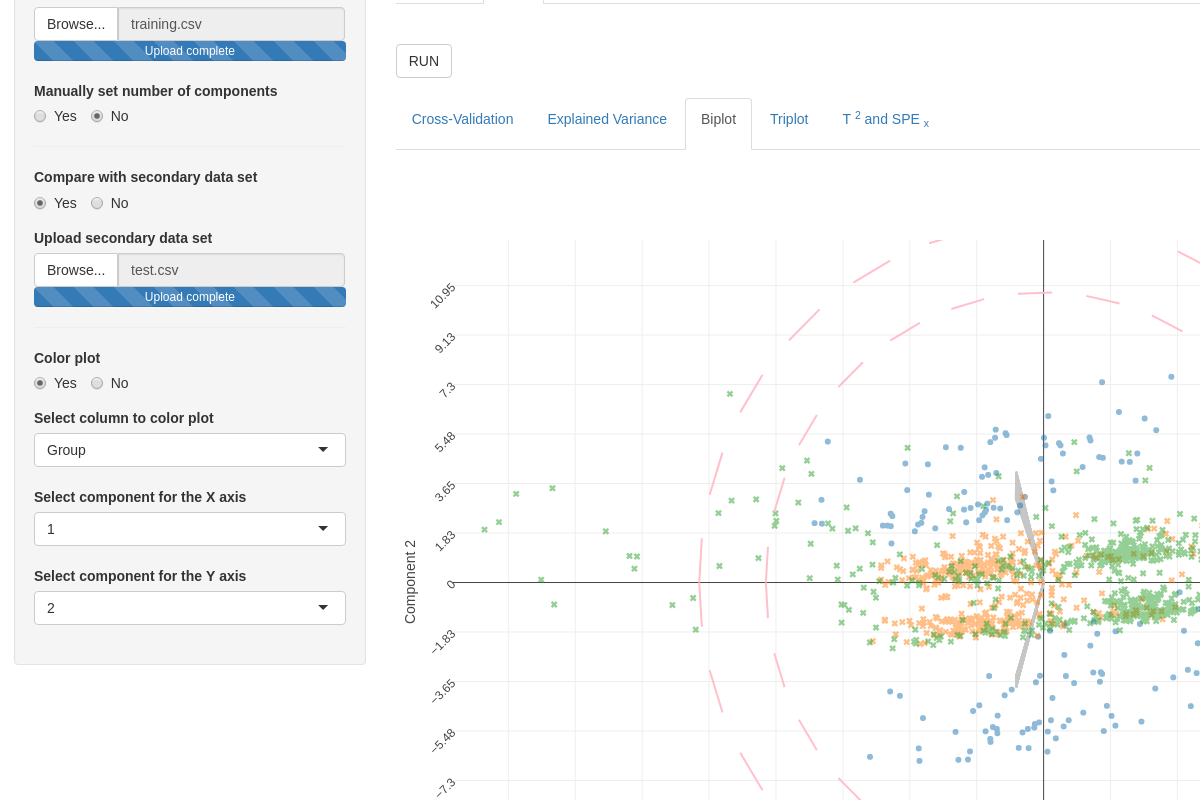

While working remotely, I also created a graphical user interface for an internal statistical analysis tool, gaining hands-on experience with data manipulation and plotting libraries. This experience confirmed my passion for applied machine learning and data science, and I'm grateful for the trust and autonomy I was given throughout the projects.